Fibre Reinforced Plastic (FRP) or Glass Fibre Reinforced Plastic (GRP) is a high-performance composite material made from a polymer matrix reinforced with fiberglass. This combination results in a lightweight yet incredibly strong material suitable for various industrial and structural applications.

In FRP/GRP products, the polymer matrix typically epoxy or vinylester thermosetting resins binds the fiberglass, transfers loads, and protects it from environmental and mechanical damage. For applications such as FRP rebars, this structure offers excellent strength, corrosion resistance, and long-term durability, making it a superior alternative to traditional materials like steel.

FRP rebars do not rust or corrode, making them ideal for harsh environments such as marine structures, chemical plants, and coastal infrastructure.

Offers excellent tensile strength while being significantly lighter than steel — easier to transport, handle, and install.

Electrically and magnetically neutral, making them suitable for sensitive environments like MRI rooms, power plants, and tunnels.

Exceptional resistance to chemicals, moisture, and environmental degradation ensures extended service life with no maintenance.

Performs well across a wide range of temperatures and resists chemical attack from acids, salts, and alkalis.

Can be manufactured in various shapes, sizes, and strengths based on specific application requirements.

Lightweight and flexible — reduces construction time, labor fatigue, and equipment requirements.

Lower carbon footprint in some applications due to lighter transport loads and longer lifespan.

Provides excellent bond strength and performs effectively in reinforced concrete structures.

This table shows how to replace metal rebars with FTC GFRP rebars based on tensile strength equivalence.

| Metal Rebars | FTC GFRP Rebars | |||

|

|

|

|||

|

Diameter |

Weight (Per 12 meter bar) |

Equals to |

Diameter |

Weight (Per 12 meter bar) |

|

- |

- |

= |

3.0 mm |

0.185 kg |

|

- |

- |

= |

3.5 mm |

0.280 kg |

|

06 mm |

2.75 kg |

= |

4.5 mm |

0.468 kg |

|

08 mm |

4.74 kg |

= |

6.0 mm |

0.570 kg |

|

10 mm |

7.40 kg |

= |

7.0 mm |

0.900 kg |

|

12 mm |

10.65 kg |

= |

8.0 mm |

1.200 kg |

|

14 mm |

14.52 kg |

= |

10.0 mm |

1.600 kg |

|

16 mm |

18.93 kg |

= |

12.0 mm |

2.400 kg |

|

18 mm |

24.00 kg |

= |

14.0 mm |

3.240 kg |

|

22 mm |

35.76 kg |

= |

16.0 mm |

4.870 kg |

|

25 mm |

46.22 kg |

= |

18.0 mm |

6.280 kg |

|

28 mm |

58.02 kg |

= |

20.0 mm |

8.080 kg |

|

32 mm |

75.79 kg |

= |

22.0 mm |

9.800 kg |

|

40 mm |

118.52 kg |

= |

25.0 mm |

11.670 kg |

*"Kindly consult your structural engineer/architect for further guidance."

| Parameter | TMT Steel Rebars | FTC GFRP Rebars | Comparision |

|

Density |

7850 kg/m3 |

2000-2100 |

Lower |

|

Tensile Strength |

500-600 mpa |

1000+mpa |

Stronger |

|

Shear Strength |

120 |

>150 |

Higher |

|

Elongation (%) |

15% (min) |

3% (max) |

Lower |

|

Cost |

Higher |

Lower |

Cost Effective |

|

Life Span |

50 Years |

80+ Years |

More Durable |

|

Corrosion Resistance |

No |

Yes |

More Durable |

|

Electric Conductivity |

Yes |

No |

Risk Free |

|

Thermal Conductivity |

Yes |

No |

Does Not Transfer Heat |

|

Modulas of Elasticity (GPD) |

170-200 |

>50 |

Lower |

|

Concrete Covering |

35mm-45mm |

>20mm |

Lower Concrete Volume |

|

Magnetic Behaviour |

Yes |

>No |

Non Magnetic |

|

Effect on the Eco System |

High |

Low |

40% Less CO2 emission |

Ideal for structures exposed to salts and moisture due to corrosion resistance

Used in jetties, docks, seawalls, & piers where saltwater corrosion in a major concern

Useful in TBM launch/retrieval shafts & temporary supports due to ease of cutting & non-conductive properties

Resists chemical attacks in highly corrosive environments

Reinforces highways, toll plazas, & runways for long-term durability

Lightweight & non-corrosive solution for earth retention systems

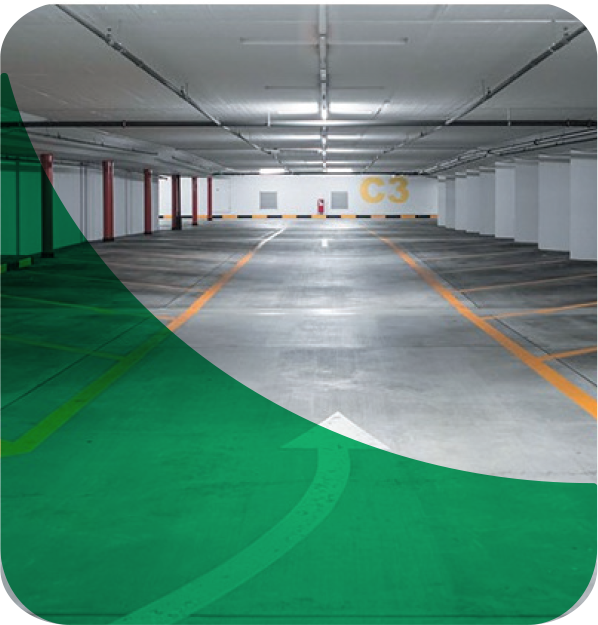

Eliminates rust-related damage from vehicle emissions and moisture

Maintains strength and integrity despite constant contact with water and chemicals

Non-magnetic & non-conductive properties make it suitable for sensitive electromagnetic environments

GFRP’s minimal weight and high tensile strength are ideal for retrofitting old buildings without overloading them.

Used in precast beams, slabs, and foundations to increase life span and reduce maintenance

Withstands fertilizers, animal waste, and humidity in farm buildings and silos

No rust particles to contaminate products or degrade structural hygiene

Preferred for non-sparking, non-conductive reinforcement in hazardous areas

Reinforcement in platform edges, culverts, and rail underpasses where electromagnetic interference is a concern.

FTC offers a range of GFRP (Glass Fiber Reinforced Polymer) rebar formats to suit diverse construction requirements - all manufactured for durability, ease of use, and long-term performance.

These are standard, linear rebars available in various diameters and lengths.

Applications

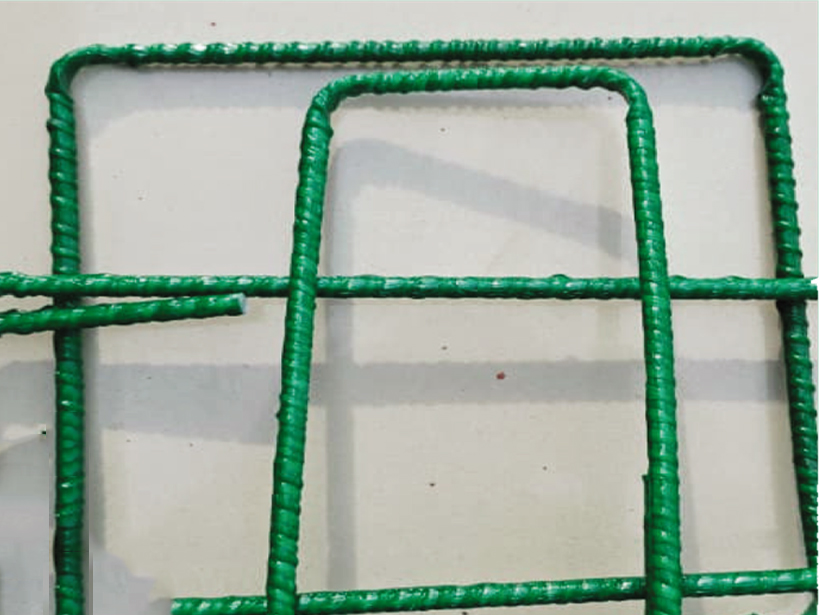

These include custom-fabricated rebars in various shapes such as stirrups, U-bends, L-bends, closed ties, or project-specific geometries.

Applications

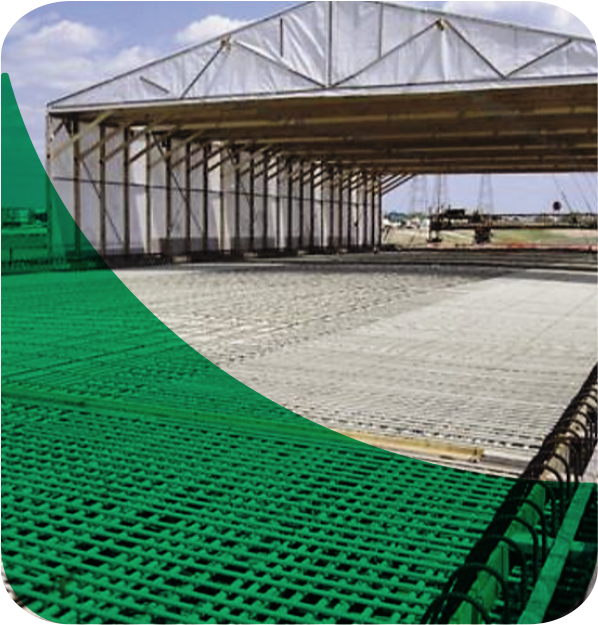

Pre-assembled mesh panels made from intersecting GFRP rebars, bonded at intersections.

ApplicationsHere are the most common issues faced with TMT bars, and how GFRP rebars can counter them

| TMT Bar Issue | How GFRP Rebars Counter It |

|

Corrosion Prone to rust in moisture, coastal air, and chemicals. |

Corrosion-Free Does not rust — ideal for marine, underground, and chemical environments. |

|

Heavy Weight High density increases transport and labor costs. |

Lightweight Up to 75% lighter — easy to lift, transport, and install. |

|

Theft During Transit or On-Site High resale scrap value leads to frequent theft. |

Low Theft Risk No scrap value — virtually no resale market. |

|

Low Chemical Resistance Vulnerable to acid, alkali, and salt exposure. |

High Chemical Resistance Withstands corrosive substances with no degradation. |

|

High Thermal & Magnetic Conductivity Not suitable for sensitive areas like MRI rooms or power facilities. |

Non-Magnetic & Low Thermal Conductivity Safe for medical, electrical, and fire-sensitive structures. |

|

Rising and Unpredictable Costs Steel prices are volatile and globally affected. |

Stable Pricing Not tied to global metal markets — more predictable budgeting. |

|

High Lifecycle Cost Maintenance, repair, and corrosion protection add up over time. |

Low Lifecycle Cost Durability reduces maintenance and long-term expenses. |

|

Excessive Scrap & Waste Cutting and shaping leads to on-site material waste. |

Low Scrap Generation Easy to cut and shape with minimal waste. |

|

Limited Durability in Harsh Environments Needs coatings or special treatment. |

Naturally Durable Performs in coastal, submerged, and chemically aggressive zones without coatings. |