FiberTech Composite is one of the most celebrated pultruded gratings manufacturers India with an unbeatable and globally acknowledged range of FRP gratings. Pultruded gratings have been widely used in commercial settings. FiberTech’s FRP gratings India have emerged as a contemporary solution to the problems arising from use of traditional material like steel and iron.

Being in the list of top FRP pultruded gratings manufacturers is not an easy thing. We have worked hard and worked consistently to carve a place for ourselves. With a range of registered FRP pultruded gratings, we have thrived in the FRP gratings manufacturers industry.

A lot of companies from diverse industries have chosen us as partners over other FRP pultruded gratings manufacturers. We cater to industries like:

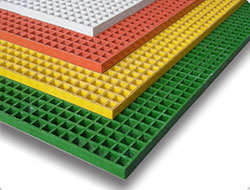

Our range of FRP gratings India can be customized for different industries depending on what they are looking for. Our pultruded FRP gratings are available as:

Fiberglass is known for certain qualities that also makes it ideal for gratings used in a variety of industries. The qualities of FRP that are desired by pultruded gratings manufacturers India are:

While choosing FRP as the desired material for pultruded gratings is easy, it is difficult to find the right manufacturer especially when you have a long list of FRP pultruded gratings manufacturers. At FiberTech, we understand that there is competition and that is why we offer:

Fiberglass or FRP grating is manufactured in a single molding process. FRP grating manufacturers use continuous pre-tensioned and pre-impregnated fiberglass roving stands, orthophthalic, thoroughly wetted using a chemical resistant polyester, isophthalic or vinyl ester halogen-free fire retardant resin system. With sturdiness and high strength, fiberglass gratings are offered in two distinct product lines, pultruded or molded.

Molded gratings available at Fiber Tech are having high strength, corrosion resistance, durability, light weight and safety features. Each of the gratings is constructed with quality materials to meet the highest international standards.

You can avail three designs of pultruded gratings- I shape bars, T shape bars and high load bars for heavy duty applications. Engineers of Fiber Tech assemble the panels mechanically and bond them chemically and also assure high corrosion resistance with a superb mechanical strength.

Benefits of using Pultruded FRP Gratings

Our latest pultruded FRP gratings are designed and manufactured for utilization in an extensive variety of modern applications that feature corrosion resistance and quality. These are used at-

You can trust Fiber Tech Global experts as they are delivering best quality range of FRP products throughout the world. Fiber Tech is a renowned manufacturer and exporter of FRP gratings and FRP products. Entire range is easy to install and maintenance free. You don’t need to maintain or clean them often.

Engineers test the entire batch first and make stringent quality checks to ensure reliability of the product. You can contact FRP pultruded gratings suppliers in India and avail great deals.

| I-Beam Size | Cross Rod Distance | Recommended |

| 25mm | 10kg/mtr. | 300kg/Sq.mtr. |

| 25mm | 12kg./mtr. | 400kg/Sq.mtr. |

| 25mm | 15kg/mtr. | 400kg/Sq.mtr. |

| 40mm | 18kg/mtr. | 750kg/Sq.mtr. |

| 40mm | 25kg/mtr. | 750kg/Sq.mtr. |

| 40mm | 30kg/mtr. | 1000kg/Sq.mtr. |

| 40mm | 40kg/mtr. | 1500kg/Sq.mtr. |

| 40mm | 45kg/mtr. | 2500kg/Sq.mtr. |

| 40mm | 50kg/mtr. | 500kg/Sq.mtr. |

Further, our products are always tested on stringent quality checks that make them more reliable for client use. Due to continuous quality checks, the maintenance costs for our products are pretty much negligible and they last longer. We avail our products in custom specifications to suit different industry demands and assure maximum profits for the same. To know more about our products and to give bulk orders for the same, contact prominent FRP Pultruded Gratings suppliers in India right away.

Fiber Tech FRP Moulded grating is manufactured in an open, heated mold system by professional skilled workers. Continuous glass roving is laid down in the mold in alternating layers in both directions and completely wetted out with resin. This continuous process produces an integral plates which provides excellent corrosion resistance as well as bi-directioanl strength.

Fiber Tech FRP Moulded grating is engineered to provide proven corrosion resistance and reliable service under extreme conditions. The interwoven square mesh construction provides bi-directional strength allowing for efficient panel usage and cutting to minimize waste. The high resin to glass ratio provides excellent service life in the most demanding applications.

| Description | Fiber Tech Grating | Hot Dip Galvanised | Stainless Steel |

| Strength to weight ratio | Excellent | Average | Average |

| Life span | Excellent | Good | Very Good |

| Life Cycle Cost effectiveness | Excellent | Good | Good |

| Chemical Resistivity | Excellent | Good | Excellent |

| Electrical Non-conductivity | Excellent | Poor | Poor |

| Rust proof Features | Excellent | Average | Excellent |

| Handling | Very easy | Difficult | Difficult |

| Installation cost | Very low | High | High |

| Anti skid | Available | Not Available | Not Available |

| Colour selection | Available | Not Available | Not Available |

| RESIN TYPE | GRATING TYPE | DESCRIPTION | APPLICATION |

| Vinyl Ester | Type VE | Superior corrosion resistance | Environment with high corrosion problems. |

| Flame resistant Vinyl Ester | Type VE-FR | Superior corrosion & Flame resitance | Environment with high corrosion requiring better flame resistance. |

| Isophthalic Polyester | Type IP | Industrial grade corrosion resistance | Used in the environments of normal or less concentration inorganic acid, alkali, etc |

| Flame resistant Isophtalic polyester | Type IP-FR | Industrial grade corrosion & Flame resistance | Used in les concentrated inorganic acidic areas requiring better flame resistance. |

| Orthophthalic polyester | Type OP | Moderate grade corrosion resistance | For use in environment which requires water & weather proof solution. |