Fiber reinforced plastic (FRP) and glass reinforced plastic (GRP) is the ultimate choice for cable trays. We at FiberTech are masters in manufacturing GRP and FRP cable trays. Our range of FRP and GRP cable trays is vast and filled with qualities that cable trays should have in order to fulfill the purpose that they are created for. We are renowned name in India’s top FRP cable trays manufacturers.

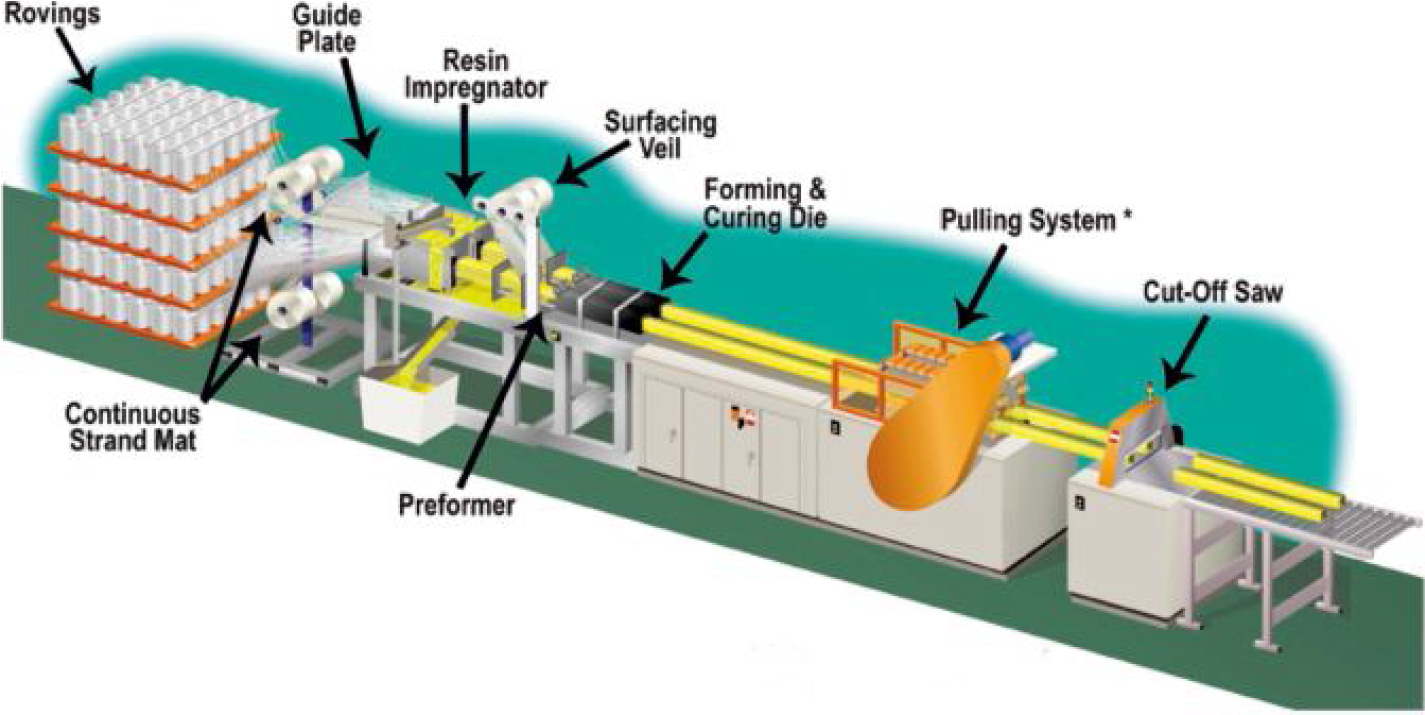

FRP Cable Trays & GRP Cable Trays Manufacturers IndiaPultrusion is a complicated process and you should always choose a trusted manufacturer who has a reputation to live up to. FiberTech has delivered quality FRP cable trays to hundreds of clients. Our FRP and GRP cable trayshave unparalleled quality and a list of loyalists.

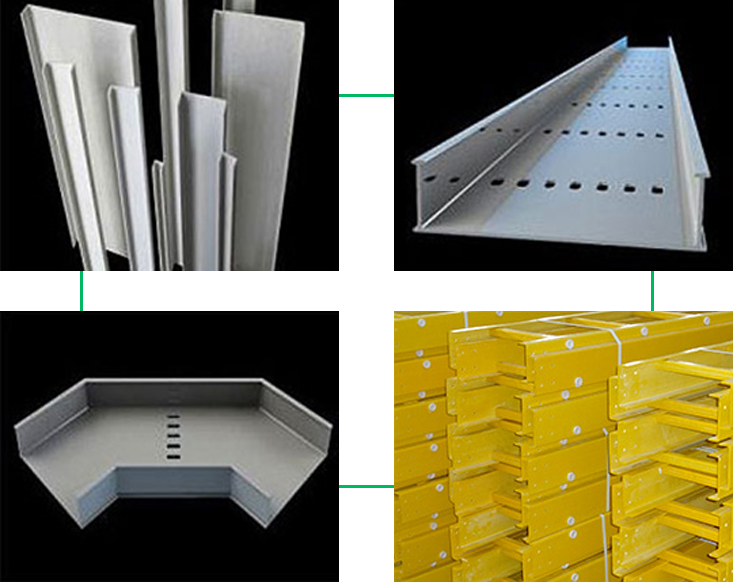

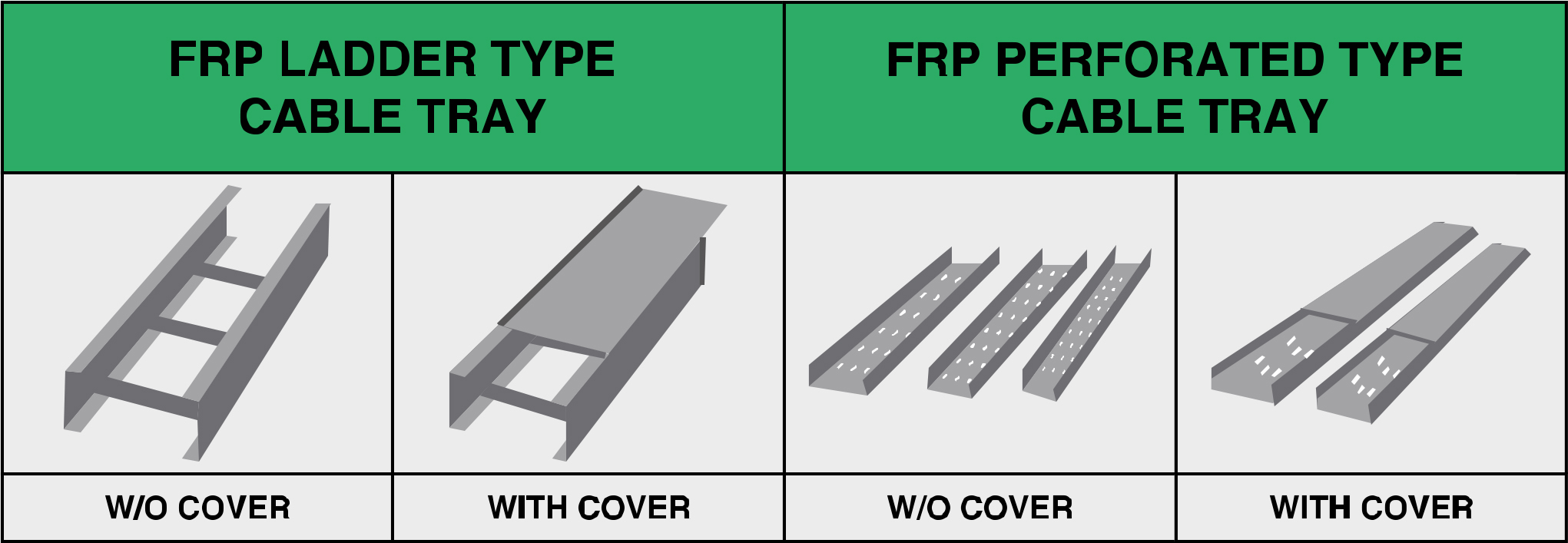

Our ladder type cable trays are designed with longitudinal sections that form a C shape. The longitudinal sections are joined by a rung that is adept at handling loads of different capacity

Perforated TypeThis is another major offering of FRP cable trays manufacturers. It is designed with sections and a solid bottom in which holes are drilled to achieve desired result.

Get What You WantAt FiberTech, we give extreme importance to the client requirements. Our sales team makes notes of every little detail that you specify and pass that on to the manufacturing team which takes care of the specification. What you get is exactly what you asked for. The quality of our GRP and FRP cable trays is unrivalled. All the properties of FRP and GRP like rust and chemical resistance, lightweight, etc. are rightly captured in our FRP and GRP cable trays making us the right FRP cable trays manufacturers for you.

Contact us at sales@fibertechglobal.com for more information on our range of cable trays.

Designs and manufactures FRP cable trays and accessoriesCable trays are designed by engineers to support power cables and control cables for outdoor and indoor applications. FRP cable trays manufactured at Fiber Tech Global are safe to use and durable for regular use. These are cost effective products produced by engineers as per NEMA BIS/consultants specification.

The range of cable trays includes-Fiber Tech Global is a trusted supplier and exporter of FRP cable trays offering vast variety of FRP products and cable trays in India and throughout the world. These products are lighter in weight and can be easily installed and transported.

All the frp range of perforated products is corrosion resistant. These products are lighter in weight and can be easily moved and transported from one place to another. You don’t need earthing for these products. These are made of UV resistant materials. The thermal conductivity is very low. These are halogen free and non toxic and have long life cycle.

Industries using our productsFor more details on FRP cable tray, contact Fiber Tech today. They are exporting and supplying comprehensive range of FRP and GRP products to the global clients from distinct industries. In FRP cable tray range, there are two designs- FRP ladder type cable tray and FRP perforated cable tray.

Standard specification is available as per below table| Width | Side Runner Ht. | Rung Width | Design Load UDL | Material |

| 100mm | 77 / 100 / 150 | 50mm | 10kg / mtr. | Polyester / Viny |

| 150mm | 77 / 100 / 150 | 75mm | 12kg / mtr. | Polyester / Viny |

| 200mm | 77 / 100 / 150 | 100mm | 15kg / mtr. | Polyester / Viny |

| 250mm | 77 / 100 / 150 | 150mm | 18kg / mtr. | Polyester / Viny |

| 300mm | 77 / 100 / 150 | 200mm | 25kg/mtr. | Polyester / Viny |

| 400mm | 77 / 100 / 150 | 300mm | 30kg/mtr. | Polyester / Viny |

| 450mm | 77 / 100 / 150 | 450mm | 40kg/mtr. | Polyester / Viny |

| 500mm | 77 / 100 / 150 | 500mm | 45kg/mtr. | Polyester / Viny |

| 600mm | 77 / 100 / 150 | 600mm | 50kg/mtr. | Polyester / Viny |

FRP/GRP cable trays made by FTC is fabricated out of different pultruded sections of advanced polyester & vinelester resins, manufactured by automatic pultrusion machine.

FRP / GRP cable trays are good replacement of G.I / M.S cable trays, which tend to corrode, erode and spread heat thus leading to power interruptions.

On the other hand FRP cable trays safe, durable, cost effective and easy to install. FTC manufactures these cable trays as per NEMA / BIS / Consultants Specification.

| Inside Width | Load Design | Material Choice |

| 50mm | 10kg/mtr. | Polyester/Vinyl |

| 75mm | 12kg./mtr. | Polyester/Vinyl |

| 100mm | 15kg/mtr. | Polyester/Vinyl |

| 150mm | 18kg/mtr. | Polyester/Vinyl |

| 200mm | 25kg/mtr. | Polyester/Vinyl |

| 300mm | 30kg/mtr. | Polyester/Vinyl |

| 450mm | 40kg/mtr. | Polyester/Vinyl |

| 500mm | 45kg/mtr. | Polyester/Vinyl |

| 600mm | 50kg/mtr. | Polyester/Vinyl |

Pultrusion is a continuous, automated closed-moulding process for a manufacturing of constant FRP Pultruded Sections and profiles. The basis process usually involves pulling of continuous fibers through a bath of resin, blended with a catalyst and then into pre-forming fixtures where the section is partially pre-shaped & excess resin is removed, It is then passed through a heated die, which deternmines the sectional geometry and finish of the final product. . He resulting high unindirectional strength profile is cut to required length and is ready to be used for Fiber Tech Cable Management System.

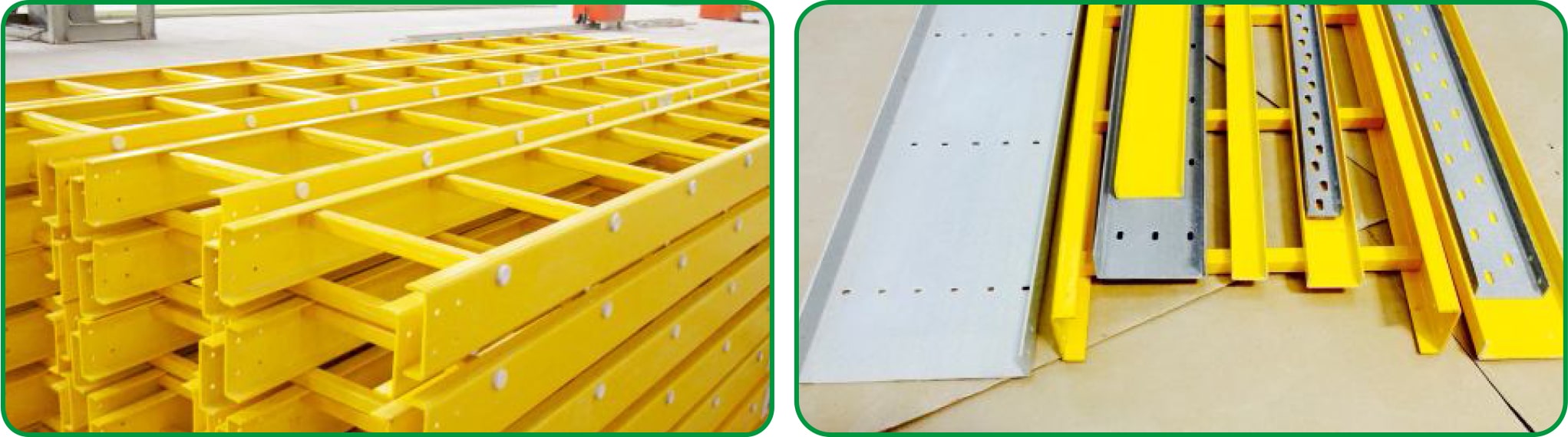

Fiber Tech offers wide range of FRP/GRP CAble Trays, supplies in various sizes. These cable trays are manufactured via Automated Pultrusion Process which ensures consistent best quality product. FRP GRP Cable Tray are extremely durable and resistant to all kind chemical attack. FRP cable tray can be used in the most corrosive and structurally demanding environments across the globe. Including, Offshore Platforms, Chemical Plants, Oil and Metal refineries, Water Treatment Plants and many more industries. Considering all kinds of instrumentations and cable runs, Fiber Tech offers two types of Cable Trays :

FRP Ladder Type Cable Trays are offered by assembling different types of combinations of Pultruded Cross Sections, Side runners and Rungs. The Rungs are epoxy bonded and fastened to demonstrate high strength against Point, Side and Uniform loads.

The Channel Type, Solid buttom, pre-drilled cable trays are designed for light loads namely instrumentation and control cables and for transition from cable trays to individual control points.

| DESCRIPTION | FIBER TECH FRP CABLE TRAYS | MILD STEEL | GALVANISED IRON |

| Chemical Resistance | Excellent | Low | Low |

| Lift Span | Excellent | Good | Low |

| Acid Fumes Resistance | Excellent | Low | Moderate |

| Electrical Conductivity | Low | High | High |

| Fire Retardant | High | High | High |

| Corrosin Resistance | Excellent | Low | Low |

| Strength to Weight Ratio | Excellent | Low | Good |

| Life Cycle Cost | Low | Moderate | Moderate |

| Rust Proof Features | Excellent | Excellent | Average |

| Ease in Installation | Excellent | Moderate | Moderate |

| Environment Impact | Low | High | High |

| Colour Selection | Excellent | NA | NA |

| Resin Type | Grating Type | Description | Application |

| Vinyl Ester | Type VE | Superior corrosion Resistance | Environment with high corrosion problems. |

| Flame Resistance Vinyl Ester | Type VE-FR | Superior corrosion & Flame Resistance | Environment with high corrosion requiring better Flame Resistance |

| Isophthalic Polyester | Flame IP | Industrial Grade corrosion Resistance | Used in the Environment of noemal or less concentration inorganic acid, alkali, etc. |

| Flame Resistance Isophthalic Polyester | Type IP-FR | Industrial Grade corrosion & Flame Resistance | Used in less concentration inorganic acid areas requiring better Flame Resistance |

| Orthophthalic Polyester | Type OP | Moderate Grade Corrosion Resistance | For use in environment which requires water & weather proof solutions. |

| Description | FRP Perforated CT | FRP Ladder Type CT |

| Resin | Polyester - Isophthalic - Vinylester | Polyester - Isophthalic - Vinylester |

| Glass | ECR Boron Free Grade | ECR Boron Free Grade |

| Length | 3 - 6 Meters | 3 Meters |

| Width | 50 - 300 MM | 150 - 1000 MM |

| Rung Construction | NA | FRP Square Tube |

| Rung Spacing | NA | 300 MM |

| Coupler Plates | GRP FRP with SS Bolts | GRP FRP with SS Bolts |

| Angel of Bends | 900 - 450 | 900 - 450 |

| Radius of Bends | 300 MM | 300 MM |

| Fire Retardant | As per IS 6746 | As per IS 6746 |

| Colour | Yellow / Grey | Yellow / Grey |

| Properties | Typical Value Test Method | Typical Value Direction | Unit | Polyester | Vinyl Ester |

| Mechanical | |||||

| Ultimate Tensile Strength | ASTM D - 638 ASTM D - 638 |

Longitudinal Transverse |

PSI PSI |

30000 7000 |

35000 10000 |

| Tensile Modulus | ASTM D - 638 ASTM D - 638 |

Longitudinal Transverse |

PSI PSI |

2.5 x 106 0.8 x 106 |

3.0 x 106 1.0 x 106 |

| Ultimate Compressive Strength | ASTM D - 695 ASTM D - 695 |

Longitudinal Transverse |

PSI PSI |

30000 15000 |

35000 20000 |

| Compressive Modulus | ASTM D - 695 ASTM D - 695 |

Longitudinal Transverse |

PSI PSI |

2.5 x 106 1.0 x 106 |

2.5 x 106 1.2 x 106 |

| Ultimate Flexural Strength | ASTM D - 790 ASTM D - 790 |

Longitudinal Transverse |

PSI PSI |

30000 10000 |

35000 14000 |

| Flexural Modulus | ASTM D - 790 ASTM D - 790 |

Longitudinal Transverse |

PSI PSI |

1.6 x 106 0.8 x 106 |

2.0 x 106 1.0 x 106 |

| Shear Strength Short Beam | ASTM D - 2344 | Longitudinal or Transverse |

PSI PSI |

5500 5500 |

7000 6000 |

| Impact Strenght-Izod Hardness - Barcol |

ASTM D - 256 ASTM D - 2583 |

Longitudinal Transverse Perpendicular |

ft.-lb./in. ft.-lb./in. |

25 4 50 |

30 5 50 |

| Electrical | |||||

| Electrical Strength Short Time -in oil |

ASTM D - 149 | Perpendicular P{arallel |

Vilts/mil. KV/in. |

200 35 |

200 35 |

| Dielectric Constant | ASTM D - 150 | Perpendicular | 5.0 | 5.0 | |

| Dissipation Factor | ASTM D - 150 | Perpendicular | 0.03 | 0.03 | |

| Arc Resistance | ASTM D - 495 | Longitudinal or transparent |

Secords Secords |

80 80 |

120 120 |

| No. | Iten Name |

| 1 | Straing Run |

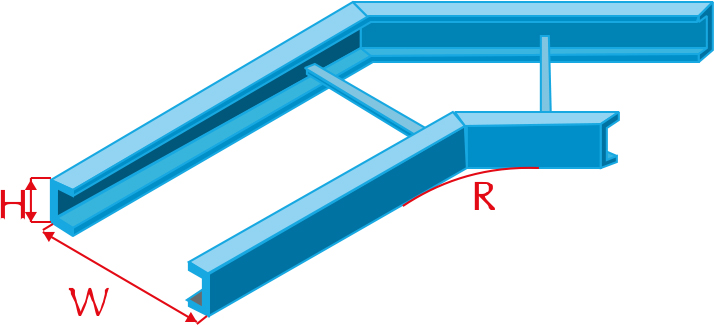

| 2 | 900 Inside Vertical Bend |

| 3 | 900 Outside Vertical Bend |

| 4 | 900 Horizontal Bend |

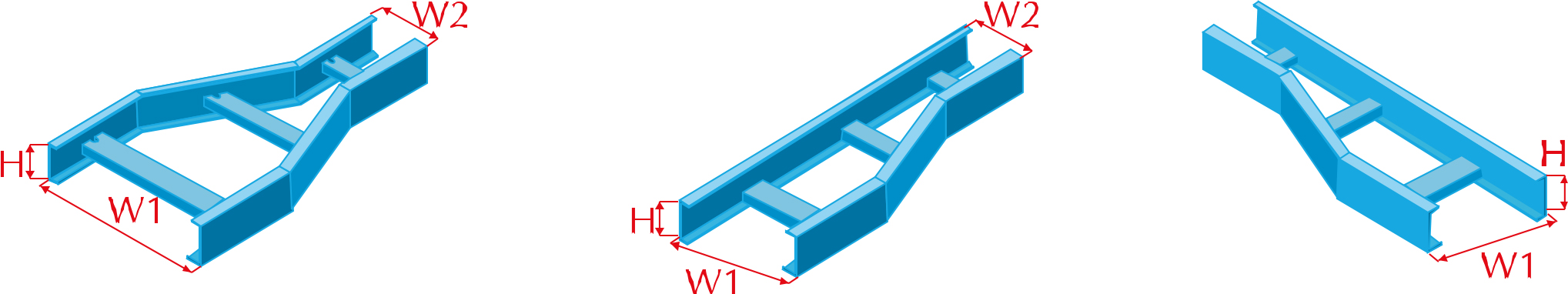

| 5 | Left Hand Reducer |

| 6 | Horizontal Cross |

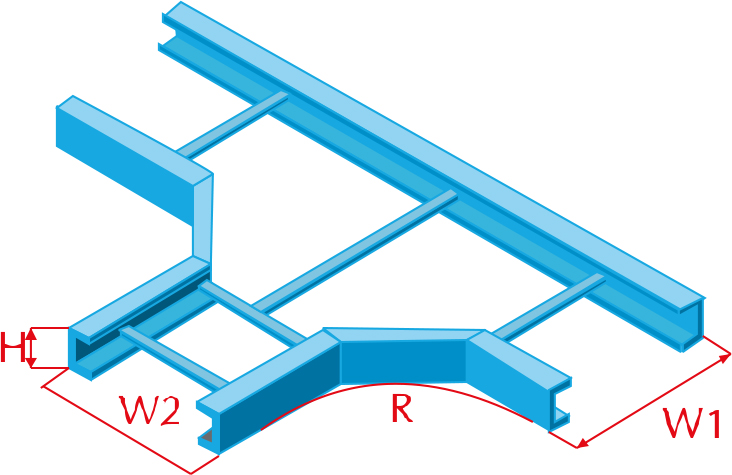

| 7 | Horizontal Tee |

| 8 | Splice Plate For Joining |

The 900 verticle bends are available to the corresponding tray type and width

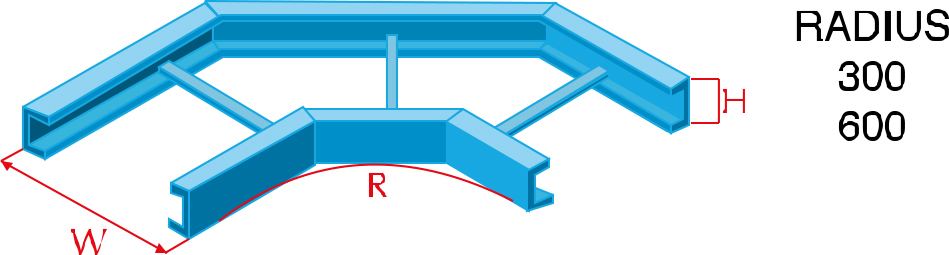

The horizontal bends are available to the corresponding tray type and width

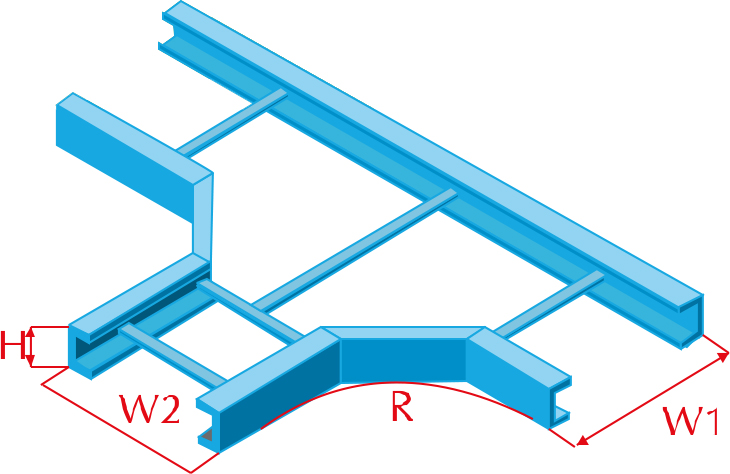

The Horizontal Tee are available to the corresponding tray type and width

300

600

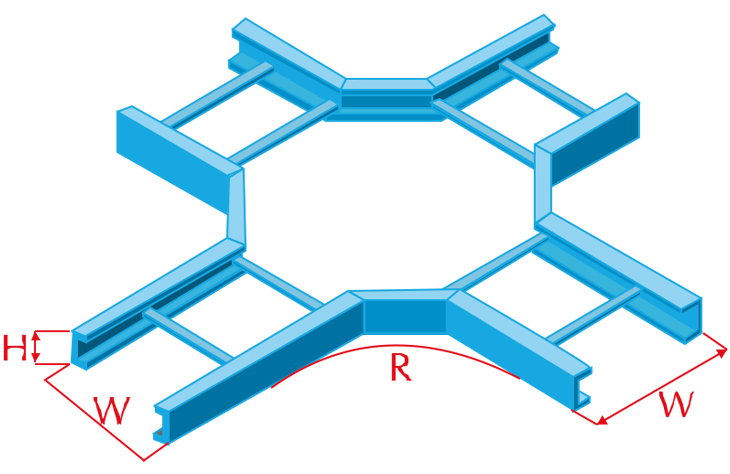

The Horizontal Cross are available to the corresponding tray type and width

300

600

The 450 Horizontal Cross are available to the corresponding tray type and width

300

600

The 450 Horizontal nemds are available to the corresponding tray type and width

300

600